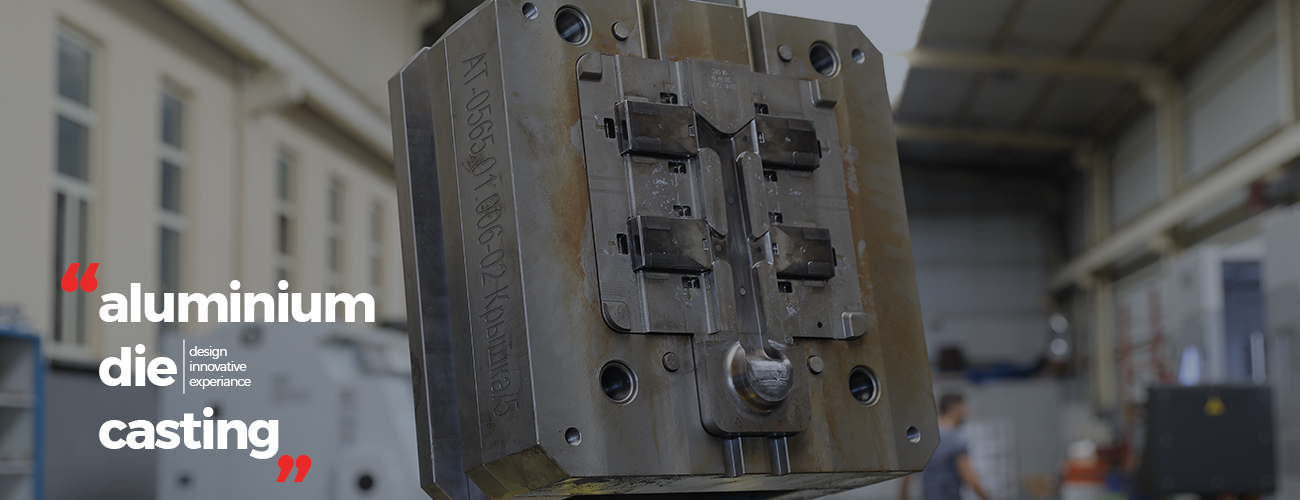

• Konya Organize Sanayi Bölgesinde 5.000 m²'lik Alüminyum Döküm Üretim Tesisi,

• Döküm alanında 40 yılı aşkın tecrübe,

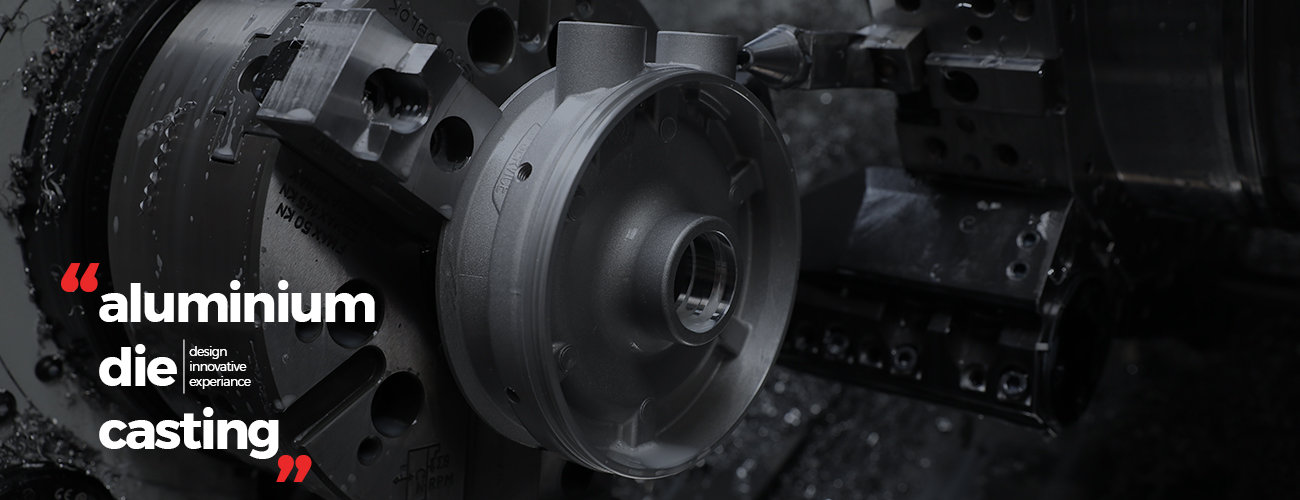

• Kalıp tasarım desteği ve üretimi, talaşlı üretim desteği dahil bitmiş ürün sağlayıcısı,

• ISO 9001:2015 Kalite Yönetim Sistemi,

• Müşteri İsteklerine en hızlı ve beklentinin üstünde çözümler,

Döktim, Konya Organize Sanayi Bölgesinde 5.000 m² alan üzerine kurulu alüminyum döküm tesislerinde alüminyum enjeksiyon döküm parçaların üretimini yapmaktadır. 40 yılı aşkın döküm ve imalat tecrübesiyle kurmuş olduğumuz tesisimizi ilave yatırımlar için ayrılmış bölümünde, yakın bir gelecekte üretim sürecine katılacak yeni makinelerle, yıllık kapasitemizi daha da arttırmayı hedefliyoruz.